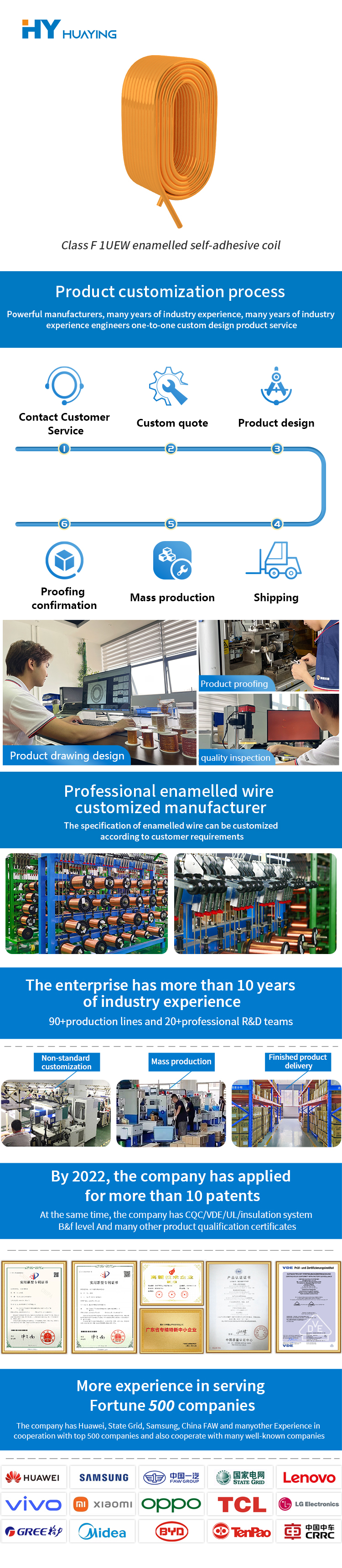

Kub thiab siab ua hauj lwm los txhim kho kev ua hauj lwm efficiency F-chav kawm 1UEW enamelled nws tus kheej-adhesive coil muaj hluav taws xob kho mob

Khoom npe: F-chav kawm 1UEW enameled self-adhesive kauj

Khoom npe: F-chav kawm 1UEW enameled self-adhesive kauj

·Self-adhesive enameled wire (self-adhesive wire), tseem hu ua self-melting wire, muaj ib txheej ntxiv ntawm nws tus kheej-nplaum xim rau saum npoo ntawm enameled hlau.

·Nws yog ib qho nyuaj heev los tsim cov txheej txheem zoo li tsis muaj coils siv hauv TVs thaum ntxov thiab qee lub tshuab hluav taws xob nrog cov xov hlau zoo tib yam. Kev tsim cov txheej txheem ntawm hom armature kauj yog qhov tshwj xeeb. Ua ntej, ib qho winding yuav tsum tau ua tiav thiab tsim, thiab tom qab ntawd txhua qhov tsim winding yog tsim rau hauv armature winding. Tib txoj kev sib sau ua ke siv los ua cov nplaum nplaum rau sab nrauv ntawm cov hlau enameled los kho nws ntawm pwm, thiab tom qab ntawd ci thiab ua kom nws zoo. Lub cev muaj zog winding txheej txheem tau ua tiav kev lag luam zoo heev. Nws yog dav siv nyob rau hauv cov khoom tseem ceeb ntawm cov khoom siv hluav taws xob xws li coreless motors, self-adhesive coils, micro-motors, electronic transformers, sensors, thiab electronic components. Kev txhawb nqa ntawm armature thiab transformer armature.

Txoj kev Bonding:

Self-adhesive txheej coated rau saum npoo ntawm tus kheej-adhesive hlau tuaj yeem tsim adhesiveness los ntawm kev txiav txim siab kub lossis tshuaj hnyav.

Kub kub / kub sib txuas:

Tag nrho Elektrisola self-nplaum txheej tuaj yeem sib koom ua ke los ntawm cua sov. Cov hlau tuaj yeem ua kom sov ncaj qha nrog cua kub thaum lub sij hawm winding txheej txheem, los yog lub qhov txhab coil tuaj yeem ua kom sov los ntawm qhov cub, los yog tam sim no tuaj yeem siv rau lub kauj tom qab winding tiav. Lub hauv paus ntsiab lus ntawm tag nrho cov txheej txheem no yog kom sov lub winding kauj mus rau ib tug kub me ntsis saum toj no lub melting kub ntawm tus kheej-nplaum txheej, thiaj li hais tias tus kheej-nplaum txheej melts thiab bonds cov xov hlau ua ke. Huab cua-los ntawm kev sib raug zoo muaj qhov zoo ntawm kev tsis tas yuav tsum muaj kev sib txuas ua ke tom qab winding. Txoj kev no yog tus nqi tsim nyog thiab feem ntau yog siv rau tus kheej-nplaum xov hlau nrog qhov ntev me dua 0.200mm. Txoj kev no tau dhau los ua neeg nyiam tshaj li ob peb xyoos dhau los nrog kev txhim kho ntawm ultra-high temperature self-adhesive txheej hom.

Qhov cub sib txuas:

Qhov cub sib txuas yog ua tiav los ntawm cua sov lub qhov txhab coil. Lub kauj yog tseem khaws cia rau ntawm lub fixture los yog tooling thaum winding, thiab tag nrho cov kauj yog rhuab nyob rau hauv lub qhov cub ntawm qhov tsim nyog kub thiab txaus lub sij hawm, thiab ces txias. Lub sijhawm cua sov nyob ntawm qhov loj ntawm lub kauj, feem ntau 10 mus rau 30 feeb. Qhov tsis zoo ntawm qhov cub sib txuas yog lub sij hawm sib txuas ntawm tus kheej ntev dua, cov txheej txheem ntxiv, thiab muaj peev xwm xav tau ntau dua ntawm cov xov hlau-qhov txhab.

Electrobonding:

Qhov no yog ua los ntawm kev siv cov hluav taws xob tam sim no rau lub coil tiav thiab ua kom muaj cua sov los ntawm nws qhov kev tiv thaiv kom ua tiav qhov kev sib txuas kom zoo. Qhov voltage thiab lub sij hawm ntawm energization nyob ntawm seb qhov luaj li cas ntawm cov hlau thiab cov coil tsim thiab yog li yuav tsum tau sim tsim rau txhua daim ntawv thov tshwj xeeb. Txoj kev no muaj qhov zoo ntawm kev ceev ceev thiab cov cua sov sib xws. Nws yog feem ntau haum rau nws tus kheej-nplaum hlau nrog hlau inch loj dua 0.200mm.

Solvent bonding:

Qee cov khaubncaws sab nraud povtseg tuaj yeem qhib tau siv cov kuab tshuaj tshwj xeeb thaum lub sijhawm coil winding txheej txheem. Thaum winding, ib qho hnyav-soaked xav ("wet winding") feem ntau yog siv los ua kom nws tus kheej-nplaum txheej. Cov txheej txheem no yuav tsum tau siv cov cuab yeej los tuav cov coils nyob rau hauv qhov chaw, thiab cov coils tau sib koom ua ke tom qab cov kuab tshuaj dries. Lub kauj yuav tsum tau muab tso rau hauv qhov cub rau ib lub voj voog kom evaporate residual hnyav thiab ua kom tiav cov txheej txheem nws tus kheej-nplaum curing txheej txheem rau qhov zoo tshaj plaws daim ntawv cog lus. Yog tias muaj cov kuab tshuaj nyob hauv lub kauj, nws yuav ua rau lub kauj tsis ua haujlwm tom qab lub sijhawm ntev.

1-300x300.jpg)