Ntau yam coil winding xov hlau, ob chav hlau, ntau hlau, ncuav mog qab zib qhov txhab tshwj xeeb inductance, parallel enamelled hlau, ntau yam specifications customized

Product Description

1. Nta:Customized specifications thiab rwb thaiv tsev txheej ntau yam, thiab txheej txheej tuaj yeem coated nrog tus kheej nplaum txheej.

2. Specification ntau yam:ib kab nrog tib lub specification tab sis txawv xim, txawv specifications thiab txawv ntau yam (ib kab specification ntau: 0.03mm-0.500mm).

3. Khoom siv:Nws yog tsuas yog siv nyob rau hauv siab thov ob / ntau xaim thaum uas tig mus rau lub qhov txhab khoom, xws li tshwj xeeb inductors, RF transformers, thiab lwm yam; Nws tuaj yeem raug mob rau hauv ob / peb / tsib coil cov zej zog nrog cov xim sib txawv thiab ua kom zoo sib xws / inductance thiab lwm yam tsis zoo, lossis rau hauv ob / peb / tsib coil cov zej zog uas muaj qhov sib txawv tab sis zoo tib yam hlau ntev.

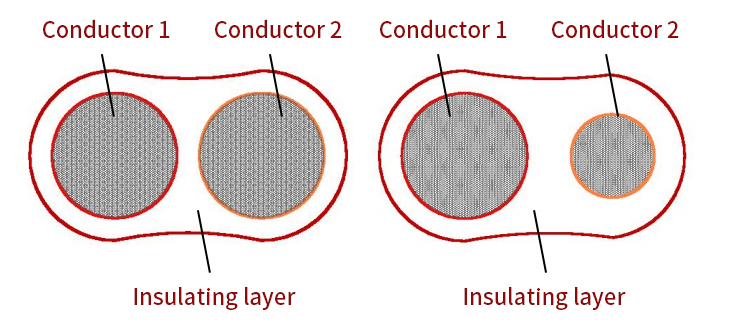

4. Daim duab schematic yog raws li nram no:

Txheej txheem ntws ntawm enamelled hlau

1. Kev them nyiaj yug:Nyob rau hauv ib txwm ua hauj lwm enamelled tshuab, feem ntau ntawm tus neeg teb xov tooj lub zog thiab lub cev muaj zog yog noj nyob rau hauv lub them nyiaj. Hloov cov nyiaj them rov qab ua rau tus neeg teb xov tooj them nyiaj ntau heev. Cov teeb meem zoo thiab kev ua haujlwm tsis ua haujlwm yog ib qho yooj yim tshwm sim ntawm txoj kab rau kab sib txuas. Txoj kev ua tau zoo yog them tawm hauv lub peev xwm loj. Tus yuam sij ntawm kev them nyiaj yog tswj qhov nro. Thaum qhov nro loj, nws yuav tsis tsuas yog nyias nyias, ua rau lub ntsej muag ntawm tus neeg xyuas pib poob qhov ci, tab sis kuj cuam tshuam rau ntau yam khoom ntawm cov hlau enamelled.

2, Stretching:Lub hom phiaj ntawm stretching yog ua kom tus neeg xyuas pib uas yog hardened vim lattice hloov thaum lub sij hawm stretching txheej txheem ntawm pwm rhuab nyob rau hauv ib tug tej yam kub thiab txias, thiaj li hais tias qhov yooj yuav tsum tau los ntawm tus txheej txheem yuav rov qab tau tom qab lub molecular lattice rearrangement. Nyob rau tib lub sijhawm, cov roj nplua nyeem thiab cov roj stain nyob ntawm tus neeg xyuas pib thaum lub sijhawm ncab tuaj yeem raug tshem tawm, kom tus neeg xyuas pib tuaj yeem pleev xim tau yooj yim thiab qhov zoo ntawm cov hlau enamelled tuaj yeem lav.

3. Painting:painting yog txheej txheem ntawm txheej txheej enamelled hlau xim rau cov hlau conductor los ua ib tug uniform xim txheej nrog ib tug tej thickness.

4 、 Khoom siv:Zoo li kev pleev xim, ci yog txheej txheem cyclic. Ua ntej, cov kuab tshuaj nyob rau hauv cov xim yog evaporated, ces kho los ua ib zaj duab xis, thiab ces cov xim yog ci. Cov pa phem yuav raug tsim tawm hauv cov txheej txheem ci, yog li lub qhov cub yuav tsum tawm tam sim ntawd. Feem ntau, catalytic combustion kub cua ncig rauv yuav tsum tau siv. Nyob rau tib lub sijhawm, tus nqi ntawm cov khoom pov tseg yuav tsum tsis txhob loj lossis me dhau. Vim tias cov cua kub ntau yuav raug muab tshem tawm hauv cov txheej txheem pov tseg, yog li cov pov tseg pov tseg yuav tsum tsis tsuas yog ua kom muaj kev ruaj ntseg thiab cov khoom zoo, tab sis kuj tsis ua rau muaj qhov kub poob ntau.

5. Cua txias:Cov hlau enamelled tawm ntawm qhov cub muaj qhov kub thiab txias, cov xim mos xim zaj duab xis thiab lub zog tsis muaj zog. Yog hais tias nws tsis txias nyob rau hauv lub sij hawm, cov xim zaj duab xis dhau los ntawm cov kev taw qhia log yuav puas, uas yuav cuam tshuam qhov zoo ntawm cov hlau enamelled.

6, Lubrication:lub lubrication ntawm enamelled hlau muaj kev sib raug zoo nrog kev nruj ntawm kev nqa. Cov roj nplua nyeem siv rau cov xaim enamelled yuav tsum tuaj yeem ua rau saum npoo ntawm cov hlau enamelled, tsis muaj kev puas tsuaj rau cov hlau, tsis muaj kev cuam tshuam rau lub zog ntawm lub reel thiab tsis cuam tshuam rau kev siv ntawm tus neeg siv. Qhov zoo tshaj plaws ntawm cov roj yog ua kom cov enamelled xaim zoo li nplua, tab sis tsis muaj cov roj pom tseeb tuaj yeem pom ntawm tes. Los ntawm ntau qhov kev xav, 1 g ntawm cov roj lubricating tuaj yeem coated rau ntawm qhov chaw ntawm 1 ㎡ enamelled hlau.

7 、 Cov khoom siv hluav taws xob:Lub hom phiaj ntawm kev xaim xaim yog qhwv cov enamelled xaim mus rau lub spool tsis tu ncua, nruj thiab sib npaug. Nws yuav tsum tau hais tias lub tshuab nqa-up yuav tsum tau tsav kom ruaj khov, tsis muaj suab nrov, nruj nruj thiab tsis tu ncua xaim.

Tom qab paub txog cov txheej txheem ntau lawm ntawm enamelled hlau nyob rau hauv kom meej, koj puas xav tias nws tsis yog yooj yim los tsim enamelled hlau uas ua tau raws li tus qauv yuav tsum tau, vim hais tias txhua kauj ruam txheej txheem, xws li ci los yog painting, yuav cuam tshuam qhov zoo ntawm enamelled hlau, thiab nws yog. kuj cuam tshuam los ntawm cov khoom siv raw, zoo, ib puag ncig, khoom siv thiab lwm yam, yog li cov khoom zoo yuav txawv. Txawm hais tias cov yam ntxwv zoo thiab cov npe ntawm ntau cov xov hlau enamelled txawv, lawv yeej muaj plaub yam khoom, xws li cov khoom siv hluav taws xob, cov khoom siv tshuaj, cov khoom hluav taws xob thiab cov khoom siv thermal.

1.jpg)

1-300x300.jpg)

2-300x300.jpg)

-300x300.jpg)

1-300x300.jpg)